Forum Energy Technologies has developed and demonstrated the ability to remotely operate work-class and observation class (Perry and Sub-Atlantic) ROVs between an offshore vessel and a remote location.

ABERDEEN, UK – Forum Energy Technologies has developed and demonstrated the ability to remotely operate work-class and observation class (Perry and Sub-Atlantic) ROVs between an offshore vessel and a remote location.

This new capability brings major opportunities to adapt operational practices in response to the latest industry drives as cost savings and reductions in HSE risks can be realized through reducing offshore crew sizes, the company said.

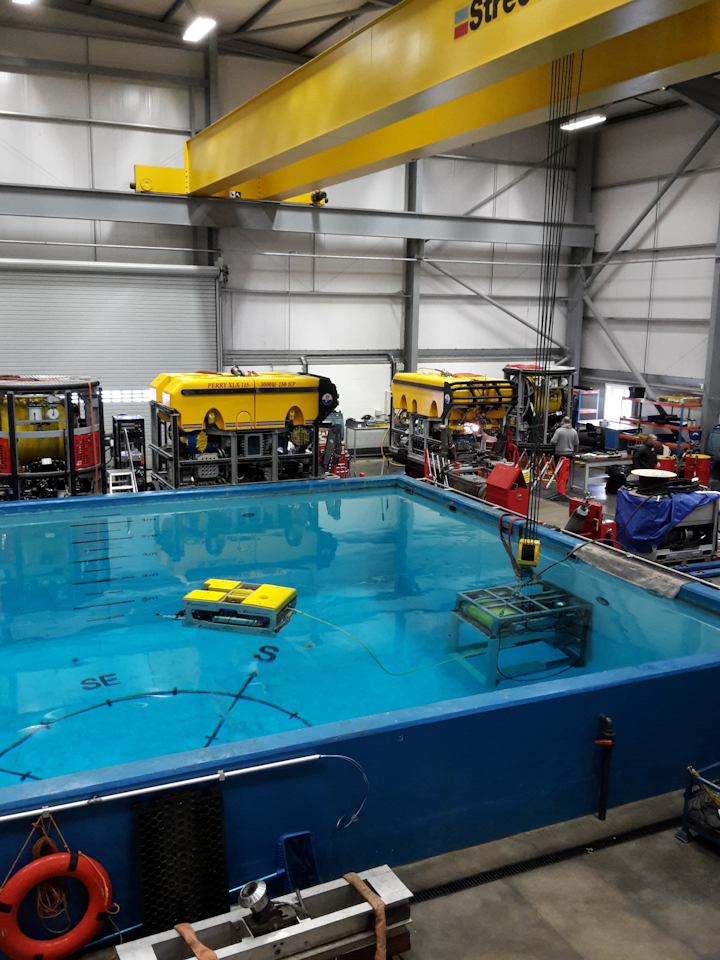

The concept of remote piloting was proven by Forum 2010 when the company successfully operated its TXLX work-class ROV in its test pool at Kirkbymoorside, UK from a TXLX console in Florida. Remote control capabilities demonstrated were camera and light controls, manifold power on/off, depth and gyro power, pan and tilt controls, manipulator controls, ROV thruster controls, auto heading controls. At that time, internet speeds were much slower than today resulting in high latency telemetry which the control system software was not equipped to counter.

However, continued development in software efficiencies which reduce the effect of network latency coupled with increased availability and reliability of the global 4G network has now allowed the company to offer remote operations on its full range of ROV systems. The company’s ICE & subCAN remote operations suites are said to provide a robust means of piloting vessel or platform-based systems from an onshore control facility via a wired, 4G or satellite connection.

The onshore hardware replicates the offshore HMI hardware and GUI so controls will be immediately familiar to operators. The Onshore Control Module provides a local hub for power and data connections.

Existing offshore control station hardware can be upgraded to allow remote control and monitoring of power systems. The Offshore Control Module interfaces with the upgraded hardware providing control and monitoring via the existing ICE/subCAN network. A key-switch, in conjunction with the software, ensures secure control of hand-over between offshore and onshore stations.

The ICE & subCAN control software applies enhanced position control when a compatible DVL and gyro are fitted to the ROV.

The system upgrade components are manufactured and delivered from Forum’s UK facility in Kirkbymoorside, Yorkshire.